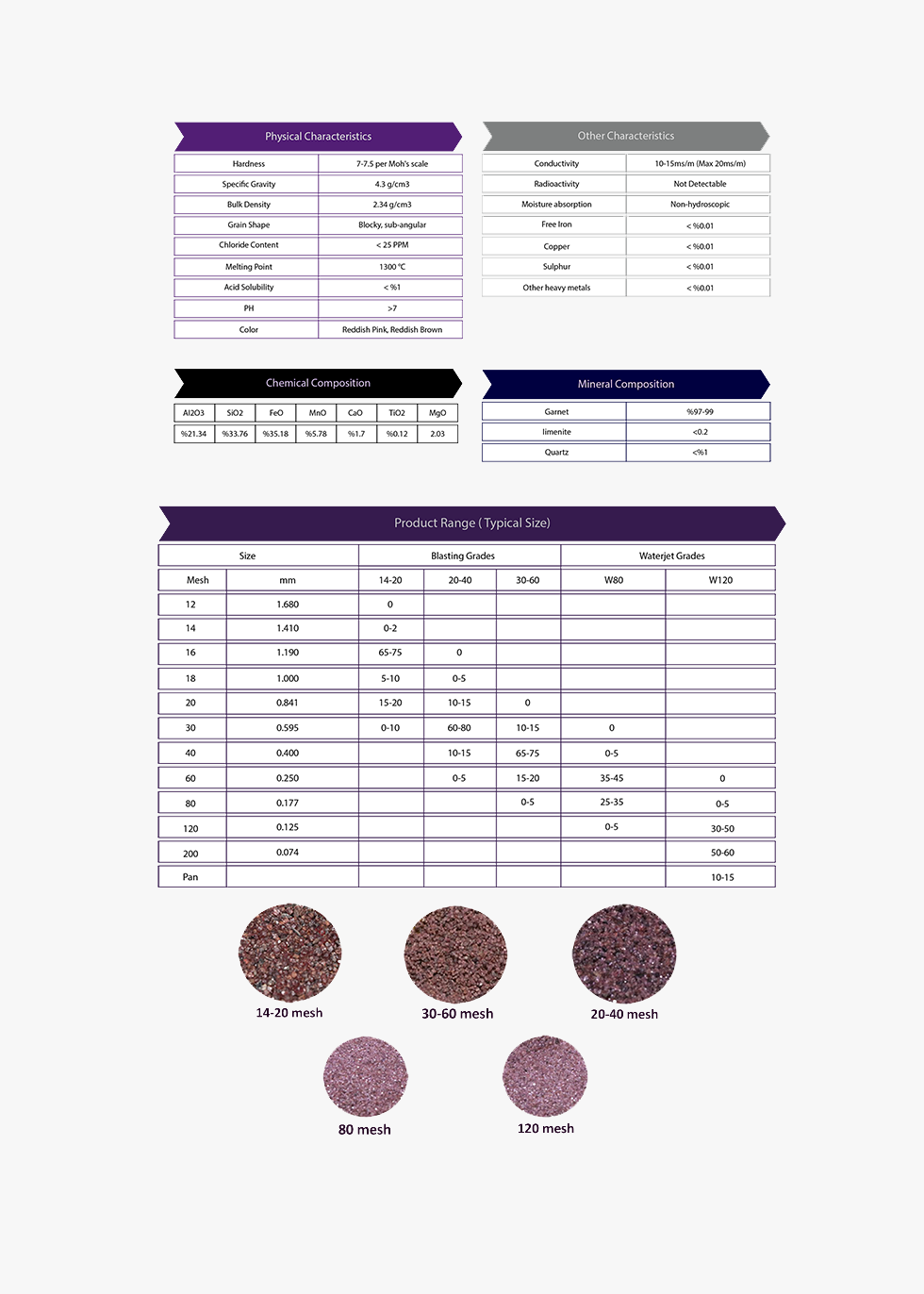

The Abrasive Garnet produced by KePA company is composed of natural almandine garnet and is recognized as one of the best types of garnet minerals in the abrasive industry.

This product serves as an effective and economical alternative to copper slag, steel minerals, and shot. Its physical and chemical uniformity ensures superior performance.

Some grades demonstrate outstanding performance in sandblasting applications across the industries like oil and petrochemical industry, maintenance, refineries, oil wells, shipbuilding and repair, workshops for sanding, bridges, railway tanks, and new constructions. Other grades are suitable for water jet cutting machines for industrial purposes.

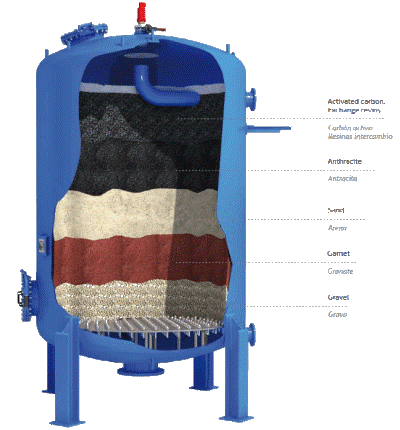

The uniformity in size and shape of the grains of our product provides excellent performance to users. Applications include cutting carbon steel, stainless steel, marble, ceramics, and road painting. Additionally, the garnet produced by this company is utilized in water treatment and filtration, as well as for the production of abrasive papers.

Garnet has many applications and is mainly used as an abrasive in abrasive blasting & water jet cutting and as a adsorbent in water filtration. It is also used in the preparation of non-skid tracks, steps, sports Ground Surface etc.

It is also used as abrasive media in coated abrasives like Grinding Wheels and belts that are used in cleaning/polishing various surfaces like glass, ceramics, wood & metals.

soluble salt and other contaminants. Sandblasting the surface treated without insert, without unfavorable convex pointed and potholes easily get clear SA3 highest level, the surface roughness can reach 30-80 microns, achieve better coating adhesion, and longer service life.

Garnet for Water Jet Cutting: Grade #80 / # 120 are perfectly suitable for the Waterjet cutting Media in the Industrial purpose. Uniformity in grain size & shape give excellent performance for the users. It is perfectly suitable for the Carbon, Steel, Stainless Steel, Marble, Ceramics and Road Painting applications.

Advantages in Waterjet Cutting

Garnet comes in two basic forms:

The latter being roughly similar to sand washed up on riversides. Our Garnet for export is produced from our crystalline almandine Garnet deposits. Thanks to its sharp edges from crushing, this kind crushed Garnet acts more like a sharp cutting tools so that it is superior to alluvial and have been shown to cut better and faster.

Sharper Edges -since our Silicon is crushed from almandine rock, it acts more like a sharp cutting tool and can cut faster and more efficiently than alluvial Garnet.

Faster Cutting – Crushed and selected from hard rock, Silicon waterjet grade Garnet produces harder and sharper edges than other waterjet abrasives. These characteristics enable our Garnet more like a hard and sharp cutting tool to finish a faster cutting.

Better Edge quality – According to the cutting material and edge quality requirement, there are various special and proper waterjet grades recommended that enable a better edge quality.

Less Dusty – Silicon Garnet has high Garnet purity and very low dust. That makes the entire cutting course more smoothly.

as it resets the filter bed more rapidly

after the bed is backflushed.Moreover, it is also effective for the elimination of heavy minerals.

Furthermore it has the benefit of

being chemically inert, recycle in

resulting in longer production to

Water treatment medium.